Unlock the Potential of Your Supply Chain with Transloading Logistics

In today’s hyper-competitive marketplace, businesses are constantly seeking ways to enhance their operational efficiency and reduce costs. One critical aspect often overlooked is the transloading logistics process. This technique allows companies to seamlessly transition goods from one mode of transportation to another, optimizing the overall logistics chain. In this comprehensive guide, we will explore the intricacies of transloading logistics, its benefits, and how it can transform the way you manage your shipping and transportation needs.

What is Transloading?

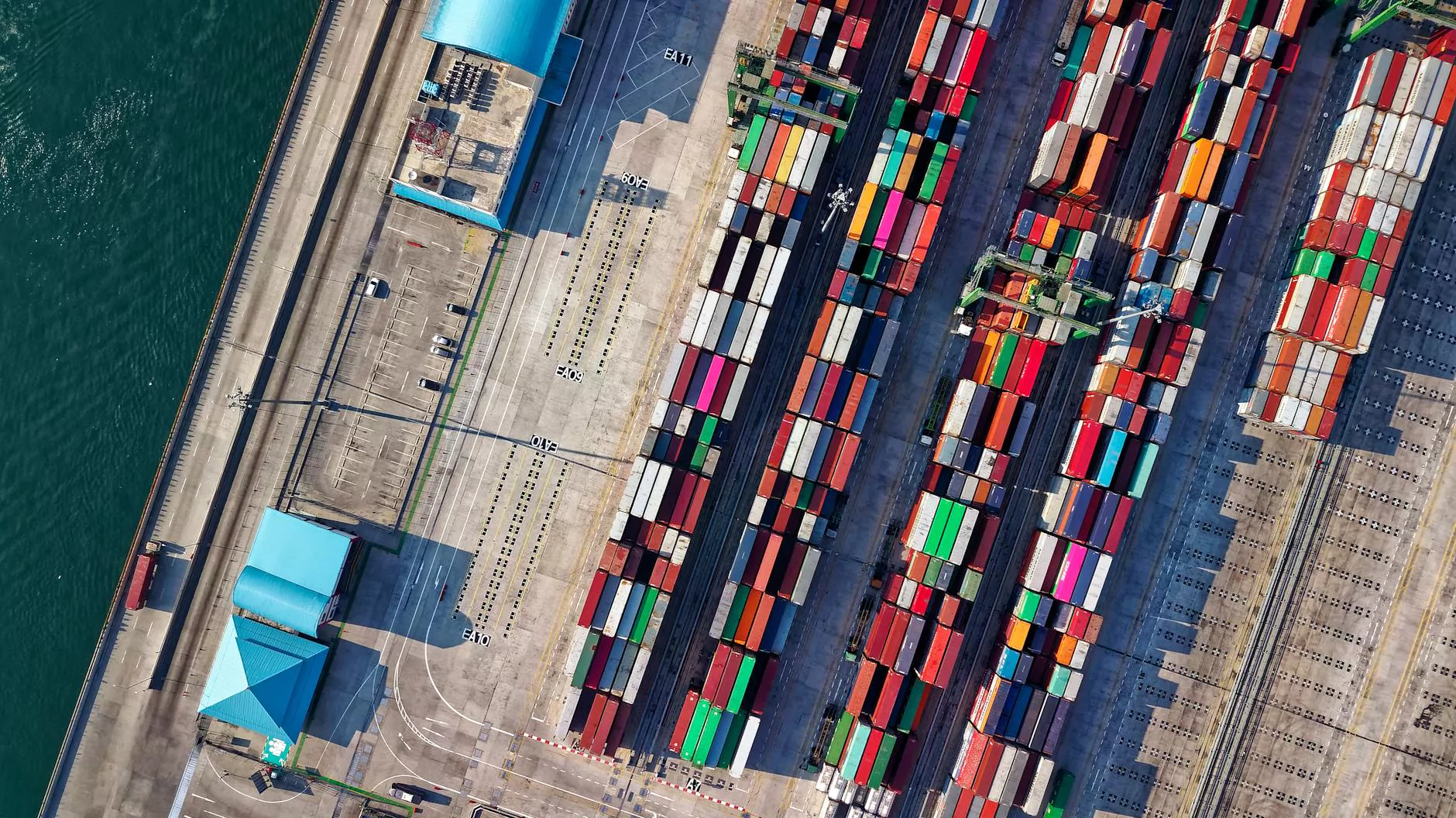

Transloading is the process of transferring goods from one transportation method to another. This typically occurs at a transloading facility, where products may be moved from trucks to trains, or from ships to trucks, among other combinations. The primary goal of this process is to maximize the efficiency of the supply chain while minimizing costs associated with shipping and handling.

The Importance of Transloading Logistics

The adoption of transloading logistics has become increasingly vital in an era where businesses are expected to deliver products faster and more efficiently. By leveraging transloading, companies can:

- Reduce Transportation Costs: By optimizing routes and consolidating shipments, businesses can achieve significant cost savings.

- Enhance Supply Chain Flexibility: Transloading provides the ability to switch transportation modes quickly, adapting to changing market demands.

- Increase Shipment Speed: Efficient transfer between carriers can lead to faster delivery times, providing a competitive edge.

- Improve Inventory Management: By utilizing multiple modes of transport, companies can streamline their inventory process and reduce stockholding costs.

The Transloading Process Explained

Step 1: Initial Arrival

The transloading process begins when goods arrive at a transloading facility. This could be a rail yard, port, or transport hub. Upon arrival, the products are checked for quality and quantity to ensure they match shipping documentation.

Step 2: Transfer Between Modes

Once the initial checks are complete, the goods are prepared for transfer. This may involve:

- Unloading from the original container.

- Consolidating smaller shipments into larger ones.

- Repackaging or palletizing products for the next leg of transport.

Step 3: Delivery

After consolidation and repacking, the goods are loaded onto the appropriate transportation mode, such as trucks or trains, for final delivery to their destination. The efficiency gained in this step can significantly reduce delivery times.

Key Benefits of Implementing Transloading Logistics

Understanding the specific benefits that transloading logistics offers can help businesses fully exploit this process:

1. Cost Efficiency

By utilizing rail for long distances and trucks for last-mile delivery, companies can significantly lower transportation expenses. The ability to optimize routes across multiple transportation modes allows businesses to find the most cost-effective solutions.

2. Scalability

Transloading logistics allows companies to easily scale their operations. Whether you're a small business expanding your geographic reach or a large corporation enhancing your supply chain, transloading provides the flexibility required for growth.

3. Improved Visibility and Control

With a streamlined transloading process, companies can gain better visibility over their supply chain. Advanced tracking systems give businesses real-time data on shipment status, allowing for proactive management of logistics operations.

4. Enhanced Risk Management

Transloading can help mitigate risks associated with supply chain disruptions. By utilizing diversified transportation methods, companies can navigate challenges such as port congestion or weather disruptions more effectively.

How to Choose the Right Transloading Partner

Finding the right transloading partner is crucial for maximizing the benefits of this logistics strategy. Here are key considerations:

1. Industry Expertise

Choose a partner with extensive experience in your industry. An experienced provider will understand the unique challenges you face and can tailor solutions specifically to your needs.

2. Location and Accessibility

Proximity to key transportation routes and ports is essential. A well-located transloading facility can minimize transportation time and costs, ensuring goods move quickly and efficiently.

3. Technology and Infrastructure

Robust technology and infrastructure are vital for effective transloading. Ensure your partner utilizes cutting-edge tracking systems, automated handling equipment, and advanced software for optimal logistics management.

4. Compliance and Safety

Verify that your transloading partner adheres to all safety regulations and industry standards. Compliance not only protects your shipment but also safeguards your company's reputation.

Case Studies: Successful Transloading Logistics Implementation

To illustrate the effectiveness of transloading logistics, let us examine a couple of successful case studies:

Case Study 1: Retail Distribution Optimization

A major retail chain implemented a transloading strategy to streamline its nationwide distribution. By utilizing rail for long-distance transport and trucks for last-mile delivery, the chain reduced transportation costs by 30%. Furthermore, delivery times improved, leading to higher customer satisfaction rates.

Case Study 2: E-commerce Growth

An e-commerce company faced challenges in meeting customer demands for rapid delivery. By adopting transloading logistics, they enhanced their supply chain by moving products from ports to regional hubs efficiently. This not only reduced shipping times but also allowed them to offer same-day delivery services in key markets.

Common Challenges in Transloading Logistics

While the benefits are clear, there are challenges in implementing transloading logistics that businesses must address:

1. Coordination Between Transport Modes

Ensuring seamless communication and coordination between different transportation methods can be complex and challenging.

2. Facility Management

Maintaining a transloading facility to ensure it meets the needs of the business is crucial. This involves managing labor, equipment, and inventory effectively.

3. Technology Adoption

Investing in technology is essential, but it can be daunting for some companies. Transitioning to a system that supports transloading logistics requires careful planning and training.

Future Trends in Transloading Logistics

As technology advances, the landscape of transloading logistics will continue to evolve. Key trends to watch include:

1. Automation

Automated handling systems and robotics will likely play a larger role in transloading facilities, improving efficiency and reducing labor costs.

2. Integration with IoT

The Internet of Things (IoT) will enhance tracking and monitoring capabilities, providing real-time data that can improve decision-making within the supply chain.

3. Environmental Considerations

As businesses become more aware of their environmental impact, sustainable practices in transloading logistics will gain prominence, pushing companies to adopt greener transportation methods.

Conclusion

Incorporating transloading logistics into your supply chain strategy can drive significant improvements in efficiency, cost-effectiveness, and flexibility. As businesses face increasing pressure to optimize operations, understanding and implementing transloading is more important than ever. By choosing the right partner and overcoming common challenges, your business can reap the rewards of a well-executed transloading strategy, positioning itself competitively in the marketplace.